Enhance Your Property with Spray Foam Insulation Columbia MO for Improved Comfort and Energy Efficiency.

Enhance Your Property with Spray Foam Insulation Columbia MO for Improved Comfort and Energy Efficiency.

Blog Article

Optimize Energy Performance With Expert Spray Foam Insulation

The search of power efficiency in residential and business spaces is significantly crucial, and professional spray foam insulation offers an engaging remedy. By successfully producing a closed obstacle, this insulation technique reduces power loss while enhancing indoor convenience and soundproofing.

Benefits of Spray Foam Insulation

When thinking about insulation choices, house owners and builders alike often discover that spray foam insulation supplies an unique combination of advantages that improve power performance and convenience. Among the main advantages is its superior thermal efficiency. Spray foam develops an airtight seal, effectively minimizing air leak and lessening power loss, which can cause significant cost savings on heating & cooling prices.

Additionally, spray foam insulation has superb sound-dampening residential or commercial properties, making it a perfect choice for producing quieter indoor settings. This is especially useful in multi-family dwellings or homes situated near active streets. The product is immune to moisture, which assists stop mold development and architectural damage, ultimately contributing to a healthier living area.

One more significant benefit is its convenience; spray foam can be applied in a range of spaces, consisting of attic rooms, creep rooms, and wall surfaces, adapting to various arrangements and needs. Moreover, it provides lasting durability, commonly lasting longer than typical insulation products. Overall, the benefits of spray foam insulation make it a compelling option for those seeking to improve power performance and overall comfort in their homes.

Exactly How Spray Foam Works

Recognizing just how spray foam insulation works is essential to appreciating its numerous advantages. Spray foam insulation consists of two major components: isocyanate and polyol material.

Furthermore, spray foam insulation flaunts exceptional soundproofing homes, making it a positive selection for both residential and industrial applications - spray foam insulation lake of the ozarks. Its capacity to resist moisture development additionally adds to a healthier interior atmosphere by decreasing the risk of mold and mildew. On the whole, understanding the mechanism behind spray foam insulation underscores its vital role in optimizing power performance and enhancing overall structure performance

Installation Process Introduction

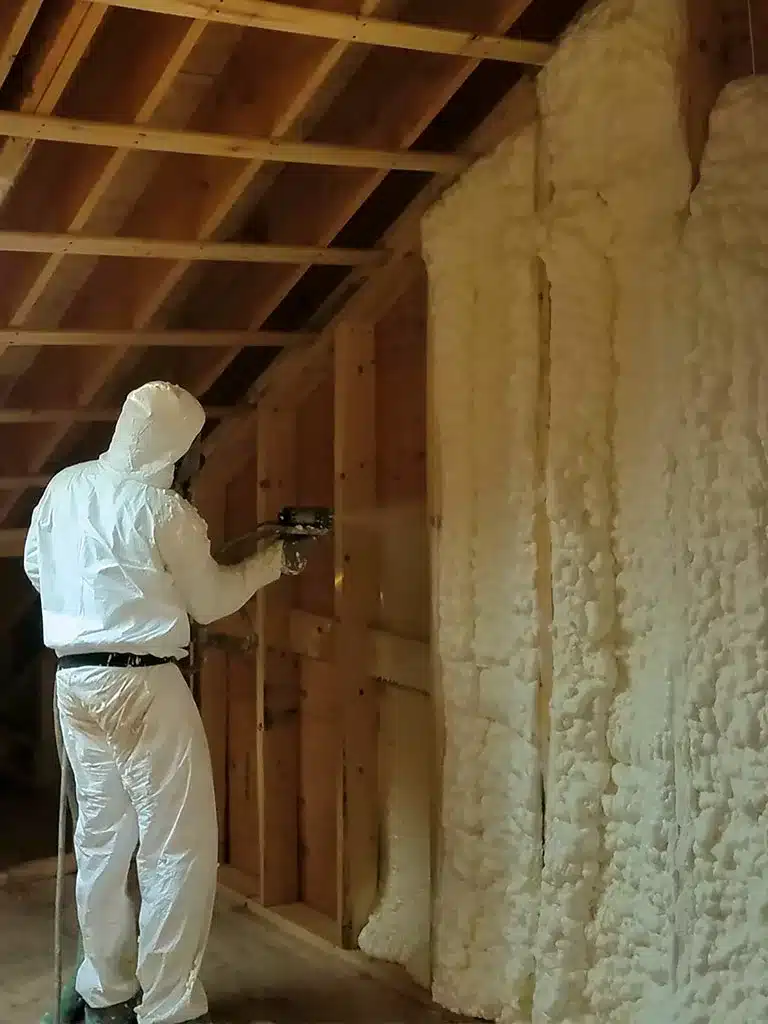

The installation procedure for spray foam insulation is a critical step that requires mindful preparation and interest to detail. The location to be protected have to be extensively checked and cleaned up to guarantee ideal bond and efficiency. This involves getting rid of any kind of particles, dust, or existing insulation products that go to this site could impede the application.

When the space is prepared, the application of spray foam can begin. Service technicians will certainly wear ideal personal protective tools (PPE) and make use of customized tools to mix and dispense the foam. The two-component blend, made from polyurethane, broadens upon application, producing a limited seal that fills up spaces and fractures, consequently boosting thermal performance.

Throughout application, it is necessary to keep track of the density of the foam to stick to maker standards and building ordinance. Professionals will usually use the foam in layers, allowing for sufficient treating time in between applications. Complying with the installment, a last inspection is conducted to ensure even protection and to assess any locations that might need extra foam.

Proper installment not only maximizes energy efficiency but likewise adds to a much healthier indoor setting, making it crucial to engage skilled specialists for the procedure.

Cost Savings and ROI

Purchasing spray foam insulation uses significant expense savings and a strong roi (ROI) for house owners and services alike. The first expense of spray foam setup might be higher than conventional insulation products; nonetheless, the long-term advantages far surpass these ahead of time expenses. Spray foam insulation significantly decreases power bills by decreasing air leaks and improving thermal efficiency, bring about reduced heating & cooling costs.

House owners can anticipate cost savings of up to 30% on their power costs, relying on their current insulation and energy usage. Furthermore, the longevity and longevity of spray foam imply that it does not need to be replaced often, lowering upkeep and replacement expenses with time. For businesses, the expense financial savings can convert into enhanced earnings, as decreased functional expenses permit reinvestment in other areas.

Moreover, numerous areas use tax obligation rewards and discounts for energy-efficient upgrades, boosting the financial advantages of spray foam insulation - spray foam insulation lake of the ozarks. Overall, the mix of instant power savings and lasting monetary advantages makes spray foam insulation a wise financial investment for any individual seeking to boost their address residential or commercial property's power performance and value

Ecological Impact and Sustainability

Substantial ecological advantages come with the usage of spray foam check it out insulation, making it a sustainable choice for modern construction and improvement tasks. One of the primary benefits is its ability to decrease energy usage considerably. By supplying superior air securing and insulation, spray foam reduces the need for heating and cooling systems to operate as regularly, straight reducing greenhouse gas discharges related to energy production.

Furthermore, numerous spray foam products are developed with eco-friendly materials, consisting of water-based formulas that eliminate unsafe volatile organic compounds (VOCs) This adds to enhanced indoor air high quality, securing owners' health while minimizing the eco-friendly footprint.

Additionally, the long life of spray foam insulation-- typically lasting over three decades-- implies less substitutes and much less waste in landfills, advertising a round economy. Its light-weight nature also minimizes transportation discharges during distribution to building websites.

In terms of lifecycle evaluation, the energy financial savings accomplished with the usage of spray foam insulation far exceed the initial environmental effect of its production. Generally, taking on spray foam insulation not only improves energy effectiveness but likewise lines up with lasting building methods that are critical for a greener future.

Conclusion

Finally, expert spray foam insulation functions as a highly reliable service for enhancing power performance and indoor comfort. Its capability to create a closed seal considerably lowers home heating and air conditioning expenses while supplying sound moistening and dampness resistance. The installation procedure, though specialist, yields substantial returns on financial investment with long-term energy cost savings. In addition, the environmental influence of lowered energy consumption straightens with sustainability goals, making spray foam insulation a sensible option for contemporary energy-conscious living.

Report this page